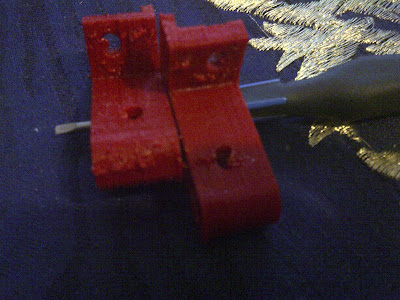

You are most likely having an extruder not retracting properly. If it's going too fast you should also be able to hear some buzzing sound coming from it.

The helpful and friendly djw_ohio in the #makergearv2 channel helped me with this so a big thanks to him. Thanks to him, I now can print like so:

Isn't that just beautiful!

What I did was the following:

Change the "Extruder Retraction Speed (mm/s)" in the "Dimension" tab to 18.0, but noticed that it didn't extrude anything when it was supposed to print smaller areas, so I decreased this to 15.0.

You can also test this in Repsnapper by remembering that in Repsnapper it's mm/min, but in Skeinforge it's mm/sec. That means, take the value in skeinforge and multiply that by 60, and use that as "speed" in the Print tab (under "Interactive Control" tab). When I did this I noticed that the value 25 in skeinforge (25 * 60 = 1500) was waay to much for it using the Sprinter firmware I've now changed to.

I also set the "Restart Extra Distance (millimeters)" from 0 to 0.015. Not that I may have to, but 0 may not be totally right. Particularly because I had some issues with the filament not being extruded in time. This value is one of those that probably needs to be tested some more though.

Next I changed the "Layer Thickness (mm)" from 0.4 to 0.3 and "Perimeter Width over Thickness (ratio)" under "Carve" from 1.4 to 1.1666667. Why? Well, that means 0.3 layer thickness times 1.1666667 = 0.35 extrustion width which is is the size of my nozzle. Actually, my nozzle extrudes ~0.43mm, but this will do for now... Will update on this when I know more...

Furter, djw_ohio explains:

"If your nozzle was 0.35, and your layer height was 0.35, you would print a perfectly round thread. At 0.35 nozzle, and 0.4 height, it got 0.05 slop in where the extruded filament lands. With a layer height of 0.3 it doesn't have any room to wiggle around before it hits the print bed. You can get any width you want really. You can use a 0.35mm nozzle and print 0.7 if you feel like it. If you slow down the feed rate, and keep squeezing just as much filament out, it makes the lines fatter."

This is quite important as per default, skeinforge is set for a 0.4 nozzle, but mine is a better 0.35 one.

"Infill Perimeter Overlap (ratio)" under "Fill" is now also set to 0.26.

"Thread Sequence Choice" was changed from "Loops -> Perimeter - > Loops" to "Infill -> Loops -> Perimeter" because that way the perimeter can get wrapped around the infill, even in mid air.

No comments:

Post a Comment