Thursday, June 30, 2011

Treadgaming Blender Logo Animation

Thursday, June 23, 2011

Blender 2.58 (stable) Released!

Blender 2.58 update log

The majority of work for 2.58 went into fixes with over 200 bugs fixed since last release but there are also quite a few useful additions worth checking out.

Prominent features (the cool stuff)

Warp Modifier:

This deformation modifier can be used to warp parts of a mesh to a new location in a very flexible way by using 2 objects to select the "from" and "to" regions with options for using a curve falloff, texture and vertex group.

Render Baking:

For high polygon models it is now possible to bake multi-resolution models using much less memory than before. There are also new bake modes: specular color, specular intensity, mirror color, mirror intensity, alpha (transparency), emission (glow)

Empty Images Display:

Instead of using background images or creating meshes with materials and image texture it's now possible to assign images directly to empty objects to use as reference images. They display in all draw modes and can use object draw options like XRay to draw over other objects.

Sculpting:

Constructive modifiers (like subdivision surface, mirror and other) were supported for sculpting mode. Sculpting could be not very accurate with such modifiers enabled, so there is a new option in the toolbar to disable applying constructive modifiers in the sculpting session.

Mesh Inset (Addon):

Mesh inset is a very useful tool with the ability to inset individual faces or a selected region.

Camera Locking:

It is now possible to move the camera using normal view port navigation by enabling "Lock Camera" in the "View" panel.

And much more! Please check the link.

Wednesday, June 22, 2011

Treadgaming Logo at crowdSPRING

http://www.crowdspring.com/project/2299107_treadgaming-logo/

The award is the lowest because I'm testing it out, and I thought it would be interesting to see what I can get for that price...

Tuesday, June 21, 2011

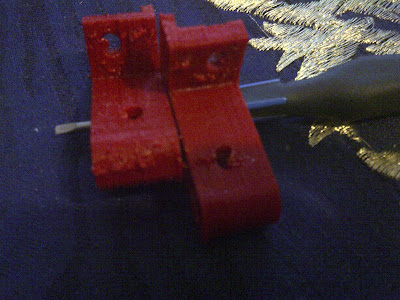

Designing the Enclosure

So, I'm not by any means done. Details will be added in time. But for now, I want the right sizes to be in place. Then, I can create some nice round corners and basically smoothen it more. I was also planing creating a plastic-only solution, with some kind of snap-on, snapping on the top part because that way I will avoid extra material, such as screws...

Animation created using Blender and GIMP. Note that this is only the bottom part...

Monday, June 6, 2011

The Ben Heck Show - Building a Custom 3D Printer

Saturday, June 4, 2011

Guess The Print

Friday, June 3, 2011

Almost Perfect 3D Print

You are most likely having an extruder not retracting properly. If it's going too fast you should also be able to hear some buzzing sound coming from it.

The helpful and friendly djw_ohio in the #makergearv2 channel helped me with this so a big thanks to him. Thanks to him, I now can print like so:

Isn't that just beautiful!

What I did was the following:

Change the "Extruder Retraction Speed (mm/s)" in the "Dimension" tab to 18.0, but noticed that it didn't extrude anything when it was supposed to print smaller areas, so I decreased this to 15.0.

You can also test this in Repsnapper by remembering that in Repsnapper it's mm/min, but in Skeinforge it's mm/sec. That means, take the value in skeinforge and multiply that by 60, and use that as "speed" in the Print tab (under "Interactive Control" tab). When I did this I noticed that the value 25 in skeinforge (25 * 60 = 1500) was waay to much for it using the Sprinter firmware I've now changed to.

I also set the "Restart Extra Distance (millimeters)" from 0 to 0.015. Not that I may have to, but 0 may not be totally right. Particularly because I had some issues with the filament not being extruded in time. This value is one of those that probably needs to be tested some more though.

Next I changed the "Layer Thickness (mm)" from 0.4 to 0.3 and "Perimeter Width over Thickness (ratio)" under "Carve" from 1.4 to 1.1666667. Why? Well, that means 0.3 layer thickness times 1.1666667 = 0.35 extrustion width which is is the size of my nozzle. Actually, my nozzle extrudes ~0.43mm, but this will do for now... Will update on this when I know more...

Furter, djw_ohio explains:

"If your nozzle was 0.35, and your layer height was 0.35, you would print a perfectly round thread. At 0.35 nozzle, and 0.4 height, it got 0.05 slop in where the extruded filament lands. With a layer height of 0.3 it doesn't have any room to wiggle around before it hits the print bed. You can get any width you want really. You can use a 0.35mm nozzle and print 0.7 if you feel like it. If you slow down the feed rate, and keep squeezing just as much filament out, it makes the lines fatter."

This is quite important as per default, skeinforge is set for a 0.4 nozzle, but mine is a better 0.35 one.

"Infill Perimeter Overlap (ratio)" under "Fill" is now also set to 0.26.

"Thread Sequence Choice" was changed from "Loops -> Perimeter - > Loops" to "Infill -> Loops -> Perimeter" because that way the perimeter can get wrapped around the infill, even in mid air.